Chronicles of Complementary, Alternative & Integrative Medicine

Research Article

Value Chain Analysis of Turmeric Subsector In Surkhet District of Nepal

Chhetri GB*, Devkota D and Sharma B

Department of Plant pathology, Agriculture and Forestry University, Rampur Chitwan, Nepal.

*Corresponding author: Ganesh Bhat Chhetri, Department of Plant pathology, Agriculture and Forestry University, Rampur Chitwan, Nepal.

Citation: Chhetri GB, Devkota D, Sharma B (2019) Value Chain Analysis of Turmeric Subsector In Surkhet District of Nepal. Chronic Complement Altern Integra Med: CCAIM-100010

Received date: 22 November 2019; Accepted date: 29 December, 2019; Published date: 03 January, 2020

Abstract

Turmeric (Curcuma longa) is a high value spice crop of high medicinal and economic concern. It has been using in Ayurveda and medicinal propose from centuries which helps to boost up digestive system, circulatory system, nervous system and immune system 60 household respondents were selected using simple random technique without replacement from Beriganga Municipality, Barahataal Village Municipality and Chaukune village Municipality. 4 co-operatives were selected from each level randomly and 5 respondents from each co-operative, i.e. 20 respondents from each local level. 3 spice industries and 7 traders were selected purposively. Secondary data were collected from secondary sources like PMAMP, journal articles, MOAD etc. Descriptive statistics, benefit cost analysis, value chain analysis were carried out. The study reveals that 81.67% of population were engaged in agriculture occupation as a primary source of income. The BC ratio of fresh, dry and powder turmeric was found to be 1.30, 1.09 and 1.36 (machinery), 1.16 (Dhiki Jhato) respectively. Similarly, the cost of production of fresh dry and powder turmeric was found to be NRs. 18.46, NRs. 119.20 and NRs. 162.92 (machinery), NRs.189.87 (Dhiki Jhato) respectively. Market margin of fresh, dry and powder turmeric was found to be NRs. 6.03, NRs. 25.07 and NRs. 179.70 respectively. In the study area major value chain actors were providers, producers, collectors, processors, wholesalers, retailers and consumers. Insufficient technical support and improved seed rhizome, insufficient price to cover cost of production and trader’s dominance in pricing were the major problems faced by turmeric producing community. This study suggests the farmers for seed production, value addition, marketing and distribution in farm level.

Keywords: Curcumin; Crop production; Harvesting; Seed

Introduction

Turmeric (Curcuma longa, Zingiberaceae) is a perennial, rhizomatous, herbaceous plant. It is one of the most important spice crop of Nepal. Among the high value crop, turmeric covers 11 % area and 15.07% in case of production (MoAD, 2018). Pseudo stem of turmeric are used as colouring and flavouring agent. Turmeric contains more than 300 naturally occurring components including beta-carotene, ascorbic acid, calcium, flavonoids, fiber, iron, niacin, potassium, zinc, and other nutrients but the chemical having high health benefit in turmeric is curcumin. Curcumin present in turmeric prevent heart disease, acts as antioxidant, improve depression and arthritis, anti-inflammatory and also reduce Alzheimer and cancer. Fresh turmeric (Kapurkot 1) has 13.8% of powder formation ability, and 92.8% of dry turmeric is converted into powder[1]. It contains 4.89% curcumin and 6.65% aromatic oils (PMAMP, 2017). Cucurminoids helps to reduce inflammation and reduce the possibility of heart attack of patients after surgery. It helps to controls knee pain from Osteoarthritis also reduce skin irritation. However long term use may create gastrointestinal problems (NCCIH, 2018). India is the largest producer, consumer and exporter of turmeric in the world. It accounts for 80% of world turmeric production. Other major producers and exporters are Myanmar, Indonesia, Netherland, United Kingdom, Peru, Germany, China, France, and United State. India exported turmeric valued 182.53 million US dollar in 2017. In fiscal year 2073/074, 43581 kg fresh (Rs 8511000), 36565 kg powder (Rs 591000) and 1287500 kg (NRs15533700) slice or dry turmeric was imported while 139 kg (Rs 50000) fresh, 3290 Kg (NRs. 890000) powder and 25090.15 Kg slice or dry form of turmeric valued NRs. 7572000 was exported.

Study of value chain in turmeric subsector can play significant role in policy making and preparation, planning of new project work. To provide the actual condition of small land holding farmers and to analyses linkage between stakeholders working in turmeric subsector, this study will be applicable. This research helps to investigate the evidence of value chain status of turmeric subsector in Surkhet district. This research helps to establish the linkage between stakeholders and service providers is the major challenge in series work to meet the demand and supply of value added product to maintain value chain governance. That enables the sustainable and balanced relation between the actors to maintain a favorable business environment. The major objective is to determine the actual need of production unit to consumption unit through the value chain approach by market information system for transfer of technology.

Materials and Methods

In this section, research site selection, research design, sampling technique, sampling population, sampling size, sampling methods and data analysis techniques are studied.

Site Selection: On the basis of statistical analysis and review, Surkhet district was selected purposively in 2019 due to high potential of turmeric production, marketing channel and value addition process[1]. To collect authentic data and minimise sampling error, 3 local level of Surkhet district was selected according to their potential production accessibility of researcher, budget and time constraints and key informant interview with Mr. Padam Subedi (Agriculture officer at PMAMP zone implementation unit ginger/ turmeric) Bheriganga municipality, Barahataal village municipality and Chaukune village municipality were selected.

Preliminary study: For the purpose of preliminary study, pilot survey was carried out to gather the statistical information of the target area. That information includes socioeconomic, demographic, topographic information about turmeric cultivation and marketing along with the relationship with stakeholders. This study was useful in the preparation of questionnaire[2].

Sample size, sampling techniques and sampling procedures: Farmers, village traders/middle man/ agent/ companies, and service providers were the focus of this research. 4 co-operatives were selected randomly in each local level and 5 farmers were randomly sampled through lottery system to make sample size 20 household in each local level. So the total sample size is 60 households. Similarly, in 3 local level total 12 co-operatives were sampled for Key informant interview. 7 major traders were interviewed and data was taken and 2 major processing units/ companies were surveyed. Service provider Prime Minister Agriculture Modernisation Project (PMAMP zone implementation unit Surkhet ginger/ turmeric) and High Value Agriculture Project in High hills and Mountains (HVAP) were selected purposively[3].

Methods and technique of data collection

Primary data: Semi structured questionnaire was developed for primary data purpose. Farmers are the major source of information. Turmeric farmers and their real problems were collected through household survey and KII for primary data[4].

Household survey: 60 households were randomly selected from 3 local levels and 4 co-operatives of each level through simple random sampling. To know the current status of turmeric farmers and to share knowledge, information and perception questionnaire survey was conducted. Open ended and close ended questions were formed from where useful information were gathered.

Key Information Interview (KII): The experienced personalities and export in turmeric cultivating farmers were selected purposively. Zone officer, local leaders and presidents of co-operatives were the major key informants.Series of questions about the present scenario of turmeric production area, yield, productivity, number of farmers involved in turmeric cultivation and economic activities were asked.

Observation: Field visit and several observations were carried out in the production and marketing units including their problems, limitations, scope, constraints and opportunities.

Secondary data: Secondary data were gathered from journals, relevant articles, newspapers, zone office, MOAD, krishi diary (AITC), HVAP, Ministry of Agriculture, internet etc. Production area, productivity, yield of different districts and trend analysis of Surkhet was carried out.

Data analysis method: The primary and secondary information collected from the field survey and other methods were analyzed by using Statistical Package of Social Science (SPSS) and Micro-Soft Excel for calculating benefit cost ratio, producers share, chain performance, value addition etc. at different stages of value chains.The primary and secondary information collected from field visit, questionnaire and KII were analysed through Statistical Package for Social Science (SPSS) and Microsoft Excel for the calculation of benefit cost ratio, market margin, value chain performance, producers share etc. Both descriptive and analytical methods were used to analyse data. The outputs were represented through pie chart, regression line, timeline, bar diagram, and Tables[5].

Economics of production and marketing system

Cost of production: It is the total cost incurred in the production process including fixed cost and variable cost.

Fixed cost =Cost of land (NRs.) + Depreciation cost of farm equipmentd andmachinery(NRs.) + Repair and maintenance cost (NRs.)

Cdeptec

Variable cost = Total cost of inputs + Total Cost of Labour

Where,

Input cost include cost of seed, manure, packaging materials, transportation andcommunication and miscellaneous cost (NRs.)

Labour cost includes cost of bullocks, field preparation FYM placement and planting, mulch collection, weeding, spraying, irrigation, harvesting, cleaning, grading, sorting, packaging, marketing and transportation (NRs.)

Gross return: It is the total revenue after the quantity sold.

Gross return = Quantity (Kg) *Price per unit (NRs.)

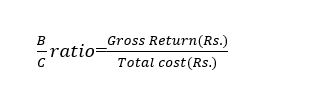

Benefit cost analysis: Gross return of production of turmeric and total cost for production were used to analyse the B/C ratio. Following formula is used to calculate B/C ratio;

Where,Gross return was calculated from the income of sold product (NRs.)

The total cost of production was calculated by summation of variable cost and fixed costincurred in the production process (NRs.)

Market margin: Market margin is the difference between the price purchases by consumer to the price received by producer.

Market margin = price of commodity – price received by farmer

Producer’s share: Producer’s share is the amount received by producer to the amount purchased by consumer. It is expressed in percentage.

Ps = Pp/Pc

= Pp/Pc * 100

* 100

Where,

Ps = producer’s share

Pp = Producer’s price

Pc = Price paid by consumer/retailer’s price

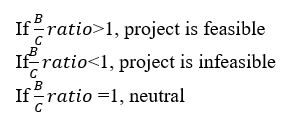

Scaling technique/ Indexing

Problems related to production and marketing is ranked by using scaling technique/ indexing. These problems were categorised on the basis of severity of problems. The index was calculated by using following formula;

Results and Discussion

Economic analysis: Economic analysis of turmeric cultivation includes, cost of production, benefit cost ratio analysis of fresh, dried and powder form, value chain function and market margin.

Cost of production: Cost of production in turmeric cultivation includes, fixed cost and variable cost. Land rent, depreciation cost of machinery and repair maintenance cost are fixed cost whereas input cost, labour cost and other miscellaneous costs are included in variable cost.Cost of production of fresh turmeric was found to be NRs. 8200.30 per ropani. Among all cost, land rent occupy 6.09%, input cost occupy 54.51% and labour cost occupy 39.39%. Out of total cost, seed rhizome covers 31.37% and manure and FYM covers 16.36%. While packaging, communication, land preparation, FYM placement and planning, mulch collection, weeding/irrigation, harvesting/grading/cleaning/sorting, marketing and miscellaneous covers 0.3%, 0.16%, 6.63%, 10.22%, 10.36%, 0.96%, 9.95%, 1.24% and 6.24% of total cost of production. Production of fresh turmeric was found to be 461.43 kg and average loss was found to be 17.14 Kg (3.71%) in one ropani of land. Production of 1 Kg fresh turmeric, Rs.18.46 is incurred.

Turmeric has various form of value addition. Githi and powder are the major value added form after cleaning, sorting and grading. To produce 1 Kg of githi, 5.18 Kg fresh turmeric is used. During githi production process, 2% handling and drying loss occurs. Rs.119.20 was incurred to produce a Kg of githi.

Powder is the final value added form of turmeric in the consumption unit in Surkhet district. 90% of githi was converted into powder.By means of machinery, 1% loss of turmeric occurs during handling and packaging process. Rs.162.92 was incurred to produce 1 Kg of turmeric powder by using machinery. 51.67% of total ho usehold were using machinery and 41.67% household were using traditional Dhiki Jhato technique in powder production process while remaining 6.66% household were not performing machinery and Dhiki Jhato.Additional cost of production of powder turmeric Machinery (84.03 Kg).

Dhiki Jhato is the traditional and conventional method used in the powder formation process. This method is labour inefficient. 1.5% handling and packaging loss was found from this technique. During the production of 1 Kg, Rs.189.87 was incurred. Additional cost of production of powder turmeric Dhiki Jhato (84.03 Kg).

Benefit cost ratio: Turmeric has different value added form i.e. githi, powder etc. In one ropani area, B/C ratio was found to be 1.30 of fresh turmeric, 1.09 of githi, 1.36 of powder formed by machinery and 1.16 of powder formed by Dhiki Jhato.

Distribution of cost and margin: Table 10illustrates the marketing margin of different value added forms of turmeric and linkage with value chain actors. Field study reveals that, cost of production of per kg fresh turmeric was NRs. 18.46 including 3.71% post-harvest loss. Farm gate price of fresh turmeric was NRs.23.97/kg with profit margin NRs.5.41/kg. To produce 1kg dry turmeric NRs.119.20 is incurred including 2% loss in farmer’s field. They sold dry turmeric at price NRs.129.93/kg at farm gate. By using machinery farmer produce turmeric powder at NRs.162.92/kg however per kg cost reaches NRS.189.87 including 1% and 1.5% handling losses and sold to consumer at price NRs.220.30/kg respectively. From the social survey the market margin of fresh, dry and powder turmeric was found to be NRs.6.03/kg, NRs.25.07/kg and NRs.179.70/kg respectively.

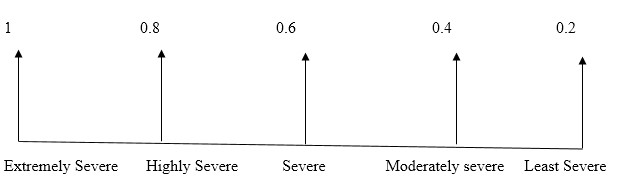

Value share of Turmeric: Field survey, 2019 reveals that the 48.36% of total production was sold by producer and 25.38% was utilised for household consumption and powder formation while 23.06% was stored for seed purpose and remaining 3.71% was lost during value addition.

Site visit and survey shows that, out of total sold fresh turmeric 25.01% of was sold to groups or co-operatives, 45.71% was sold to local trader 29.26% was sold to other companies, and middle man/ agents. Farmers are performing value addition activity in case of turmeric commodity by cleaning, sorting, grading, slicing, boiling, drying and grinding. Some farmers were selling dry slices and githis. Only few farmers sell dry turmeric. Maximum amount was sold to traders and some proportion was sold to co-operatives and groups.

Generally, small medium farmers process their dry turmeric to powder form in local level. Excess of turmeric, they sold to the different consumers. About 77.65% was sold directly to consumer, 11.64% was sold to neighbours and remaining 10.70% was sold to middleman/traders.

Marketing Channel

Problem Ranking: In Surkhet, there were several problems related to turmeric production and marketing. Indexing/scaling technique was employed to prioritise the problems. This method was implemented and explained below.

Production problems

SWOT analysis

SWOT analysis provides knowledge about strength and opportunities in production and marketing of turmeric subsector and also informs weakness and risk that helps in preparation and planning of business enterprise. Gathered information from FGD, KII and field survey, following situation was analysed;

Conclusion

Input providers, farmers, local collectors, co-operatives, traders, processors, wholesalers, retailers, exporters and consumers were major factors involved. Farming technique should be changed into commercial and promote improved cultivation technique for low cost of production, high production and productivity.To fulfill water demand, irrigation facility should be provided and further research should be conducted in effect and use of different organic and inorganic (plastic) mulching materials.Market information should be provided to different actors involved in chain activity in time to maintain market in equilibrium. Farmers should perform value addition and marketing through group/co-operatives.

Suggestions and recommendations

Based on the relevant, fact and findings, the following suggestions and recommendations were made on the research related to value chain analysis of turmeric subsector in Surkhet district which could be useful in policy making, project planning and further research in related studies. This could be useful to actors, stakeholders and facilitators to provide market information and to maintain equilibrium in demand and supply in domestic, national, and international market.

Figure 1: Marketing Channel of turmeric in SurkhetSource: Field survey, 2019.

|

S.N. |

Description |

Quantity |

Unit |

Rate |

Total |

|

Cost of production of fresh turmeric |

|||||

|

A |

Land rent |

1 |

Ropani |

500 |

500 |

|

B |

Cost of input |

- |

- |

- |

- |

|

1 |

Seed |

106.42 |

Kg |

24.17 |

2572.17 |

|

2 |

Manure/ FYM |

25.4 |

Doko |

52.83 |

1341.88 |

|

3 |

Packaging |

1 |

Sack Lump sum |

30.00 |

- |

|

4 |

Communication |

1 |

Lump sum |

13.94 |

- |

|

5 |

Miscellaneous |

1 |

Lump sum |

512.29 |

- |

|

C |

Cost of labor |

- |

- |

- |

- |

|

1 |

Land preparation |

0.48 |

Bullock day |

1133.33 |

544.00 |

|

2 |

FYM placement and planting |

1.48 |

Man day |

566.67 |

838.67 |

|

3 |

Mulch collection |

1.5 |

Man day |

566.67 |

850.01 |

|

4 |

Weeding/spraying/irrigation |

0.14 |

Man day |

566.67 |

79.33 |

|

5 |

Harvesting/cleaning/sorting/grading/packing |

1.44 |

Man day |

566.67 |

816.00 |

|

6 |

Marketing/transportation |

0.18 |

Lump sum |

566.67 |

102.00 |

|

Total production of fresh turmeric per ropani |

461.43 |

- |

- |

- |

|

|

Grand total cost for fresh turmeric per ropani |

- |

- |

- |

8200.30 |

|

|

Loss in kg Production after loss (Kg) Cost per kg of fresh turmeric (NRs.) |

17.14 |

3.71% |

- |

- |

|

|

444.29 |

- |

- |

- |

||

|

- |

- |

- |

18.46 |

||

Table 1: Calculation of cost of production of fresh and dried turmeric.

|

Additional cost of production of dry turmeric |

|||||

|

1 |

Boiling/ drying (444.29 Kg) |

2.50 |

Man day |

566.67 |

1416.67 |

|

2 |

Firewood and other equipment cost |

1 |

Lump sum |

400 |

400 |

|

Total cost for drying |

- |

- |

- |

10016.97 |

|

|

Total production of dry turmeric(Kg) |

- |

85.74 |

- |

- |

|

|

Loss in kg |

- |

1.71 |

(2%) |

- |

|

|

Net production after loss(Kg) |

- |

84.03 |

- |

- |

|

|

Cost per kg production of turmeric(NRs.) |

- |

- |

- |

119.20 |

|

|

Source: Field survey, 2019 |

|||||

Table 2: Estimation of additional cost of dry formation.

|

1 |

Machinery cost (51.67%) |

84.03 |

Kg |

20 |

1680.60 |

|

2 |

Packaging cost |

1 |

Lump sum |

500 |

500 |

|

Grand total cost |

- |

- |

- |

12197.57 |

|

|

Total production of powder turmeric 75.62 |

|||||

|

Loss in Kg 0.75 (1%) |

|||||

|

Net production Kg 74.87 |

|||||

|

Cost per kg of turmeric production (NRs.) 162.92 |

|||||

|

Source; Field survey, 2019 |

|||||

Table 3: Estimation of additional cost of powder formation by machinery. Figures inside parentheses indicates percentage of household involved.

|

1 |

Dhiki Jhato (41.67%) |

6.4 |

Man day |

566.67 |

3626.68 |

|

2 |

Packaging cost |

1 |

Lump sum |

500 |

500 |

|

Grand total cost |

- |

- |

- |

14143.65 |

|

|

Total production of powder turmeric kg 75.62 |

|||||

|

Loss in Kg 1.13 (1.5%) |

|||||

|

Net production Kg 74.49 |

|||||

|

Cost per kg of turmeric production (NRs.) 189.87 |

|||||

|

Source: Field survey, 2019 |

|||||

Table 4: Estimation of additional cost of powder formation by Dhiki Jhato. Figures inside parentheses indicates percentage of household involved.

|

S.N. |

Particulars |

Total cost/ ropani |

Gross revenue/ ropani |

B/C ratio |

|

1 |

Fresh |

8200.30 |

10649.63 |

1.30 |

|

2 |

Githi |

10016.97 |

10934.40 |

1.09 |

|

3 |

Powder |

- |

- |

- |

|

a |

Machinery |

12197.57 |

16596.43 |

1.36 |

|

b |

Dhiki Jhato |

14143.65 |

16512.20 |

1.16 |

|

*Average price of fresh dry and powder turmeric was Rs.23.97, Rs.130.12 and was Rs.221.67 |

||||

|

Source: Field survey, 2019 |

||||

Table 5: Estimation of BC ratio.

|

Production Problems |

Index |

Rank |

|

Insufficient technical support |

0.883217 |

1 |

|

Insufficient seed rhizome |

0.87845 |

2 |

|

Poor quality seed |

0.723533 |

3 |

|

Lack of appropriate training |

0.551933 |

4 |

|

Poor irrigation facility |

0.5138 |

5 |

|

Incidence of disease/pest |

0.304067 |

6 |

|

Unavailable input |

0.142 |

7 |

Table 6: Scaling of production problems.

|

Marketing Problems |

Index |

Rank |

|

Insufficient price to cover cost of production |

0.953333 |

1 |

|

poor marketing infrastructure |

0.913333 |

2 |

|

Traders dominance in pricing |

0.813333 |

3 |

|

Inappropriate market information system |

0.746667 |

4 |

|

No formal agreement with traders |

0.206667 |

5 |

Table 7: Scaling of marketing problems.

|

Level |

Internal strength |

Internal weakness |

|

Input |

Requires relatively less investment for production |

Lack of improved varieties |

|

Announcement of organic city (No use of inorganic compounds in turmeric) |

Less priority of government |

|

|

Relatively less requirement of irrigation |

No application of fertiliser |

|

|

Locally available mulching material, manure and human resources |

Traditional farming practices |

|

|

- |

Lack of appropriate training |

|

|

- |

No research activities |

|

|

Production |

Availability of local resistance variety against disease pest |

Low productivity |

|

High content of curcumin in locally cultivate landraces |

Lack of appropriate transfer of technology |

|

|

Availability of marginal land for turmeric cultivation |

No cropping plan |

|

|

Traditional cultivation practices, indigenous technology and knowledge |

No adoption of commercial farming |

|

|

Technical support from government and non-government organisation (HVAP, zone implementation unit etc.) |

- |

|

|

|

- |

|

|

Transfer of technology in production unit |

- |

|

|

Output |

Relatively long shelf life |

Traders dominance in price determination |

|

Daily consumption in household |

Poor market information system |

|

|

Spice crop and also has high medicinal value |

Unknown actual market demand and supply |

|

|

Pharmaceuticals, cosmetics and industrial use |

Improper marketing infrastructure |

|

|

Low postharvest and handling loss |

Lack of co-ordination with service providers |

|

|

High B/C ratio |

Lack of linkage between stakeholders |

|

|

- |

Communication gap between producers and processor |

|

|

Level |

External opportunity |

External threat |

|

Input |

Research activities and varietal improvement programme |

Degradation of landraces and local varieties |

|

Increasing number of service providers |

- |

|

|

|

Subsidy provision for small farmers and commercial farmers |

- |

|

Production |

Employment opportunity |

Emergence of new disease and pest |

|

Eco-friendly |

- |

|

|

Cover crop |

- |

|

|

Reduce soil erosion |

- |

|

|

Output |

Export potential |

Trade depended on India market |

|

Import substitution |

Forest degradation and lack of mulching materials |

|

|

Value addition |

- |

|

|

High demand from industries, companies and pharmaceuticals |

- |

Table 8: SWOT analysis.

Citation: Chhetri GB, Devkota D, Sharma B (2020) Value Chain Analysis of Turmeric Subsector InSurkhet District of Nepal. Chronic Complement Altern Integra Med: CCAIM-100010